What is PCB BOM management? How can it be used to increase productivity?

The beginning of the PCB manufacturing process includes listing the components, sub-component assembly, etc. that are required in production. In other words, create a list of materials commonly known as a BOM.

The bill of materials is essentially a detailed list of all the parts used in production. Manufacturers need to refer to the BOM at various stages to ensure that all inventory is in place and production is seamless. Proper PCB BOM management plays an important role in the following aspects:

Inventory management

Product lifecycle management

Quality control and so on.

Use BOM in production

Building a robust BOM requires input from various departments. While the engineering team can provide the specifications of the product, the procurement team can facilitate the best cost. Marketing teams use it to ensure functionality is delivered to customers.

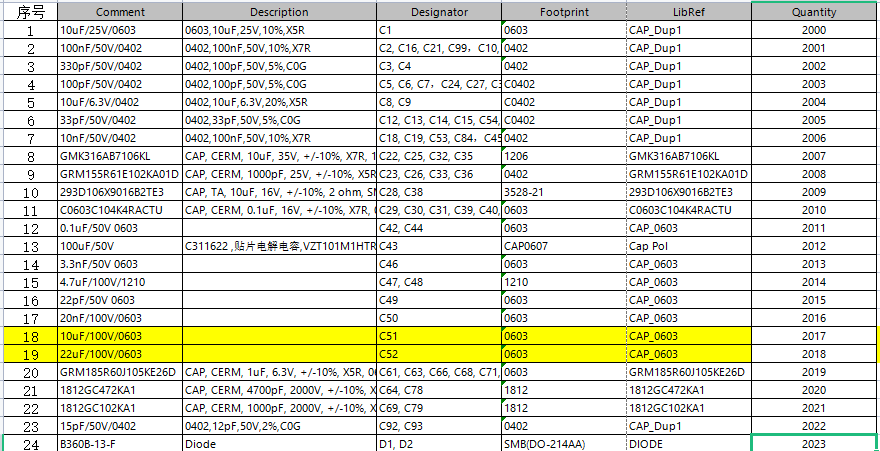

Typical information in a BOM includes:

- Part Number

- Component name

- Quantity

- Description

- Procurement stage, etc.

You may also ask: How to make a PCB BOM(Bill of Materials)?

Conversely, a bom can be either single-layer or multi-layer. The key difference between the two is that the multi-level BOM also lists the child parts needed to make the parent parts, which in turn go into the assembly of the final product.

Need PCB BOM management and methods to simplify production!

Since multiple departments need access to the BOM, old paper documents or even spreadsheets are not enough. In addition, paper documents are prone to manual errors. In addition, there is always the fear of duplication if revisions need to be made by different departments, not to mention that keeping track of different versions is a huge challenge.

PCB BOM management simplifies the process

Therefore, a cloud-based BOM solution comes in handy. BOM management goes a long way in simplifying production. Here's how:

- Centralized BOM management system control

Different departments need to access the BOM. Therefore, it is important to centrally manage system control. If you do, you can create a central repository. Importantly, it makes it easier to collaborate across departments. Therefore, any changes made will not cause any confusion & the version is easy to track.

- Secure access

Often, in addition to your internal team, you may need to provide the vendor with access to the BOM. BOM management allows you to provide secure access. In addition, you can provide access to the vendor for any changes or any other additional parties. All of this greatly reduces time delays and ensures seamless production.

- Accountability

With the BOM management solution, you can also identify revisions and edits and the people responsible for them. This ensures that accountability is maintained.

- Active evaluation of BOM components

Sourcing products that meet environmental requirements is now imperative. Therefore, provide these compliance letters to the right people in the supply chain

Rest is also important. This ensures that quality is maintained, delays are avoided and costs are controlled. With BOM management, it is easy to simplify this process.

- Improve collaboration

The BOM management process also allows you to do is utilize informal communication methods. Providing the ability to input enhances product development because it makes it easier for teams to collaborate while enhancing traceability and team continuity.

- Improve product lifecycle management

BOM also assists in product lifecycle management by:

It becomes a single repository for all information.

It records all changes and revisions and makes them traceable.

Easy to assess costs.

Ensure seamless data switching.

It connects the design and purchase processes.

- Accelerate product launches

When it comes to new product launches, speed is of the essence. In effect, a robust BOM enables you to eliminate any manufacturing or PCB manufacturing errors that stem from using the wrong parts, as well as prevent any quality problems. New product development has been significantly enhanced with the combination of mechanical, software, and electrical design across all product teams. The engineering change review schedule can be severely cut. With improved collaboration among supply chain partners, errors were significantly reduced.

It also ensures that there are no disconnected silos, while also bringing true collaboration between distributed teams. All of this has combined to lead to a fast market, which is an important source of competitive advantage.

Thus, with an automated BOM system, you can not only maintain optimal inventory, but also leverage real-time data, integrate input from all departments, and more.