-Tuesday, November 22, 2022

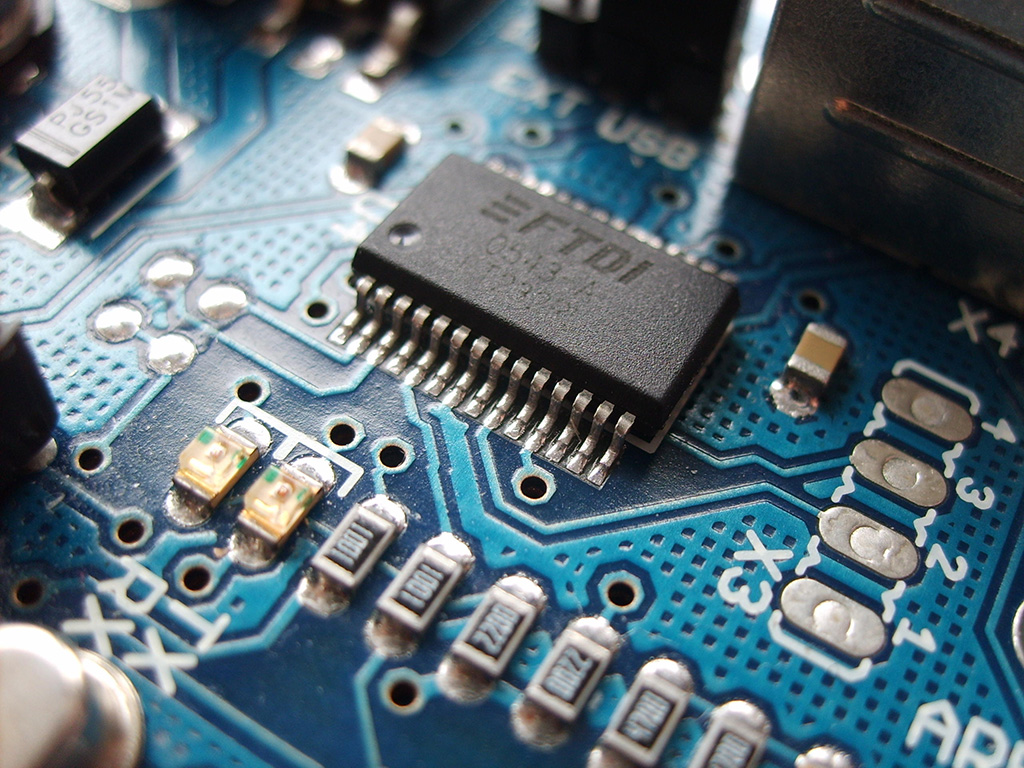

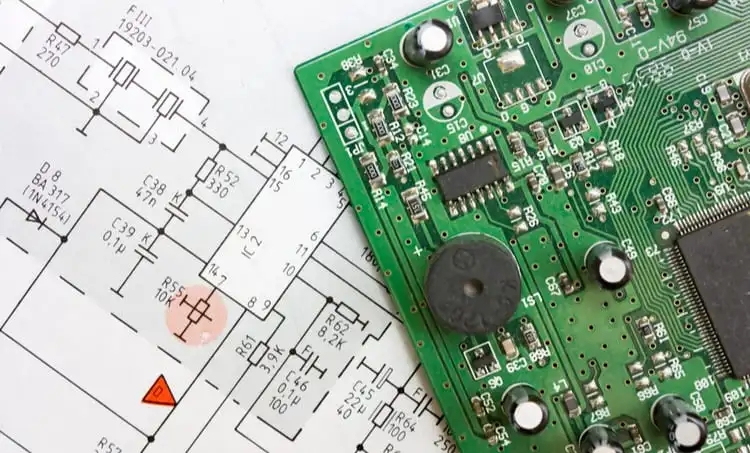

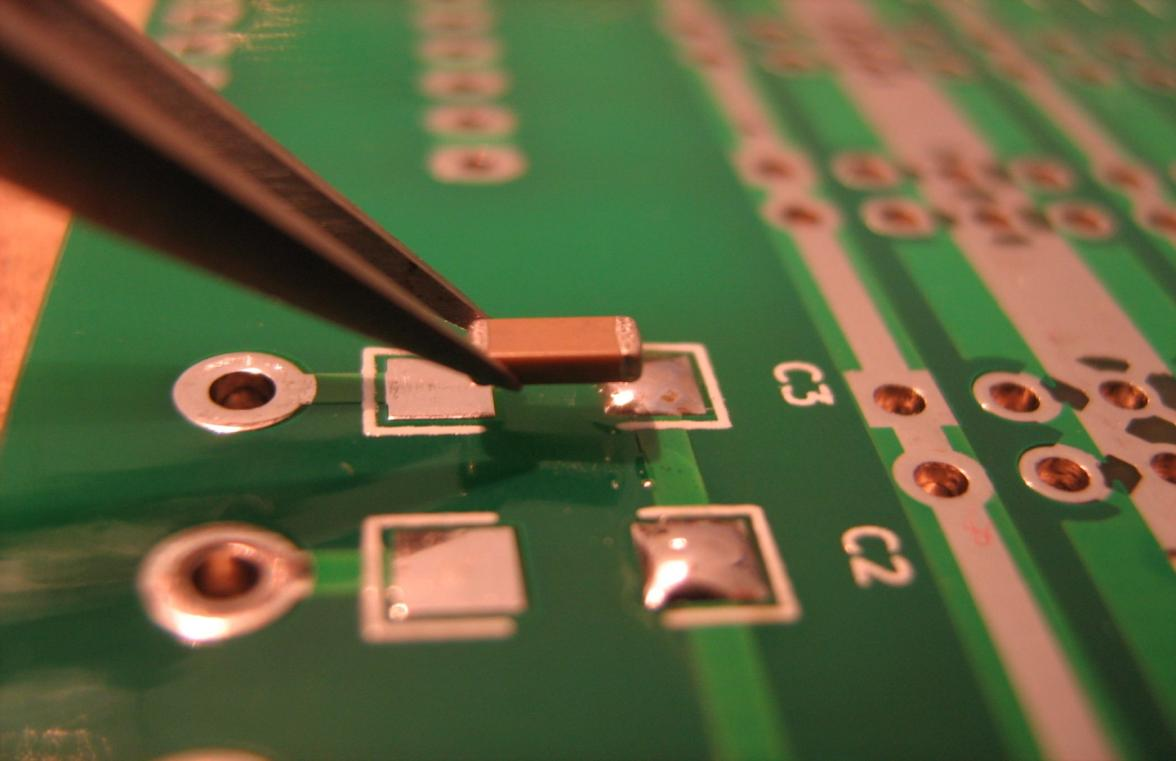

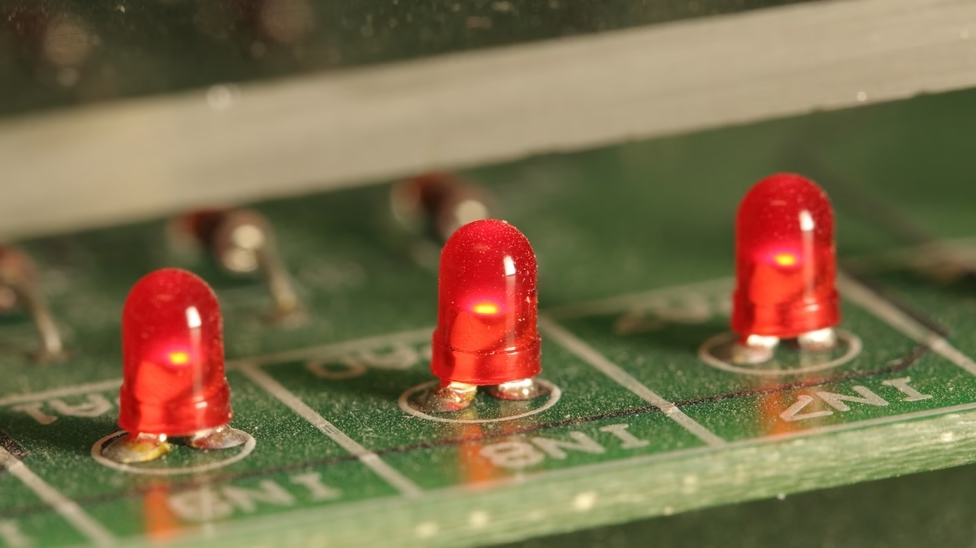

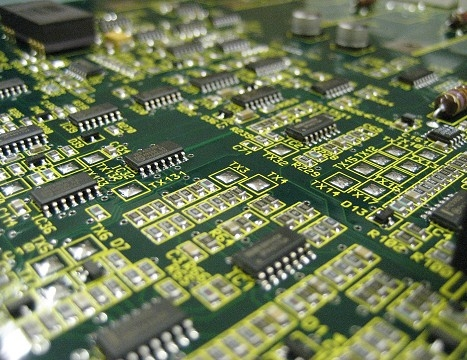

Electronic component naming conventions are used to describe semiconductor devices, passive components, and connectors used in circuit design. In the electronic component naming convention, the component family is very important for hole naming and surface mount naming. The lead spacing or positions between holes where the component leads are inserted from the first number in the naming convention for standard through-hole components.